Services

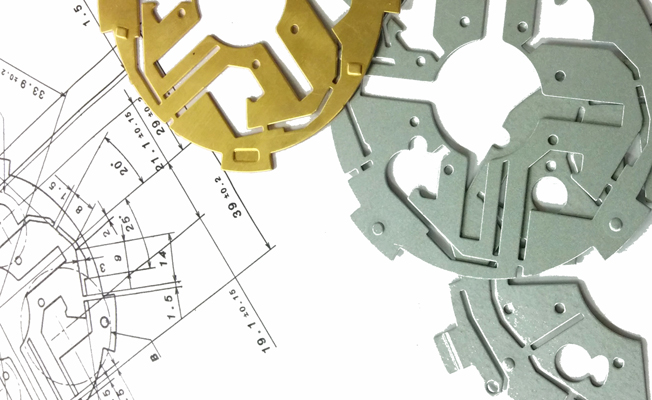

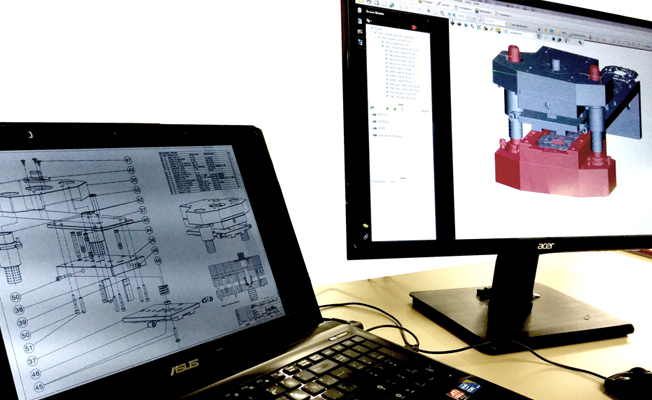

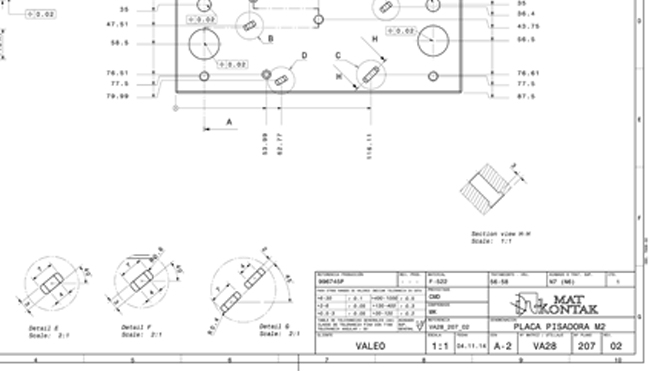

Mat-Kontak’s technical department specialises in tool and die making and carries out industrial process projects associated with metal stamping. The department develops new products and designs dies, tooling and automatisms for stamping as required. Mat-Kontak is assisted by suppliers specialised in materials and coatings for metal stamping and by trusted external designers and engineers.

We provide technical consulting to our customers during the first stage of development of new products, supplying ideas and proposals on viability, manufacturing, materials, finishes, etc. Our extensive experience as a metal stamping manufacturer means that we can ensure technically the best result for our customer.

We provide technical consulting to our customers during the first stage of development of new products, supplying ideas and proposals on viability, manufacturing, materials, finishes, etc. Our extensive experience as a metal stamping manufacturer means that we can ensure technically the best result for our customer.

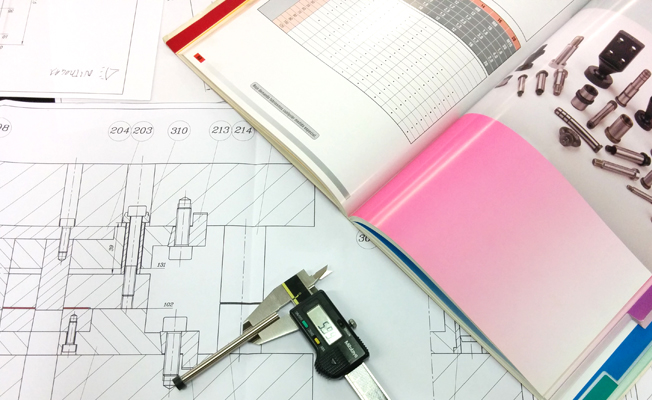

From the outset, Mat-Kontak has excelled in manufacturing high quality parts. Our quality department has implemented an efficient quality management methodology that enables us to satisfy industry requirements.

Since 1998, Mat-Kontak holds ISO 9001 quality certification, accredited by ENAC (Spanish National Accreditation Body), which attests the company’s quality processes. We have a highly skilled team and possess state-of-the-art technology. Product quality is key for all our employees. For this reason, we are constantly working to ensure standards of quality are upheld.

Since 1998, Mat-Kontak holds ISO 9001 quality certification, accredited by ENAC (Spanish National Accreditation Body), which attests the company’s quality processes. We have a highly skilled team and possess state-of-the-art technology. Product quality is key for all our employees. For this reason, we are constantly working to ensure standards of quality are upheld.

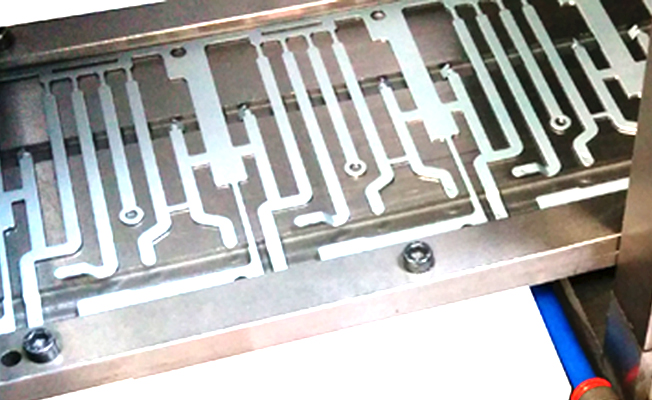

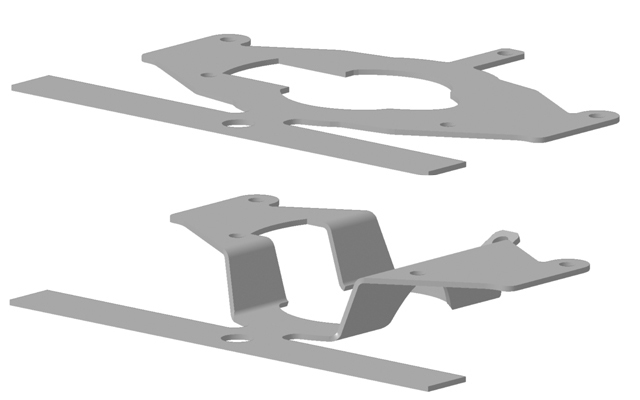

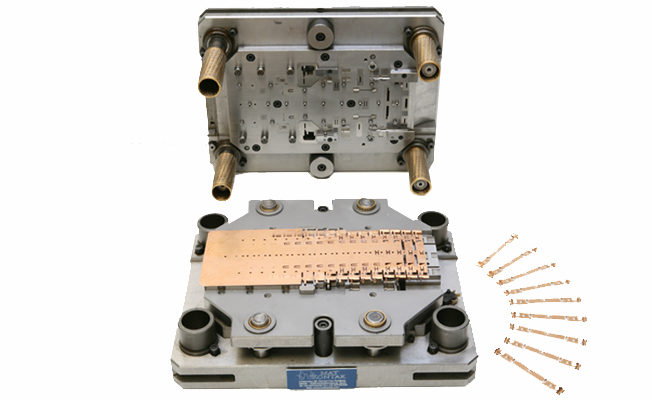

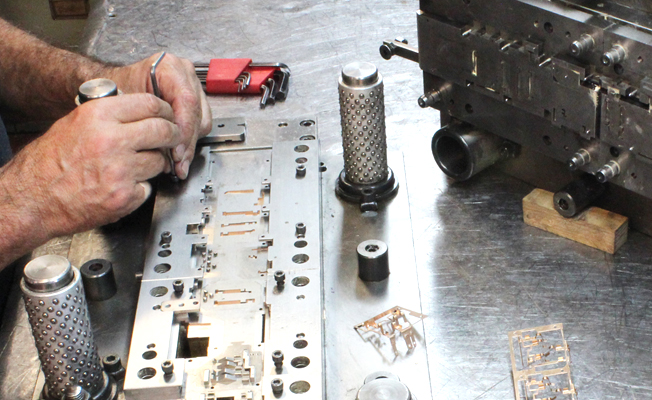

Mat-Kontak specialises in the design and manufacture of progressive stamping dies. We also manufacture other types of die and dedicated tooling. Our specialist team has extensive experience in tool and die making, assembly and adjustment in production.

At our facilities, we have all the necessary equipment and machinery for tool and die making, such as CNC machining centres, wire-cut EDM machines, and tool adjustment machinery. This equipment enables us to provide a fast turnaround on spare parts and stock for high-wear parts in dies, ensuring production continuity and product supply within the established delivery times.

At our facilities, we have all the necessary equipment and machinery for tool and die making, such as CNC machining centres, wire-cut EDM machines, and tool adjustment machinery. This equipment enables us to provide a fast turnaround on spare parts and stock for high-wear parts in dies, ensuring production continuity and product supply within the established delivery times.

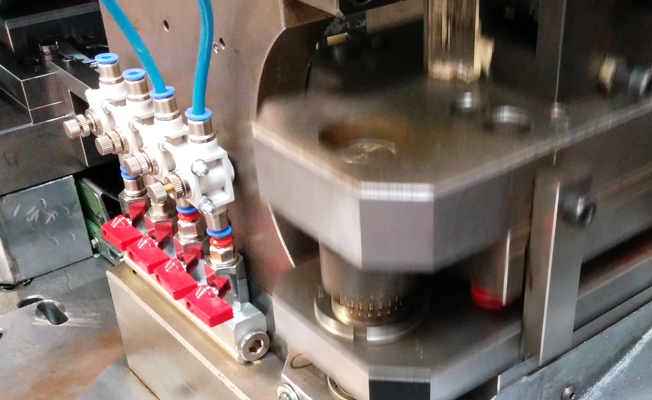

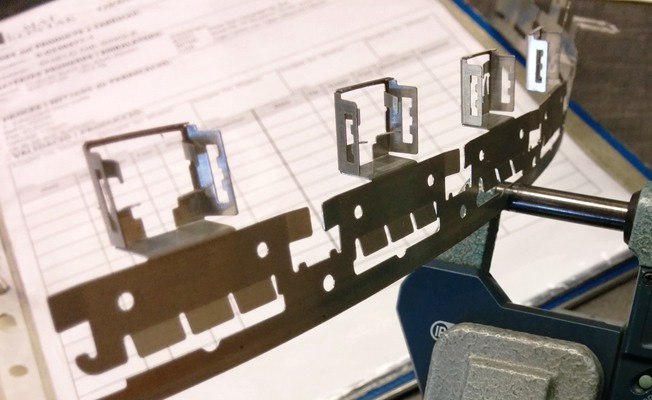

Our processes department is responsible for ensuring that our facilities operate under optimum conditions. Currently we have two industrial units equipped with presses of various tonnage and dimensions for part stamping.

We also have other auxiliary industrial equipment such as feeders, winders, lubricators, cutters, etc. used for product manufacture. During product manufacture, several types of surface finish can be defined during pre- or post-processing phases, such as tinning, plating, galvanisation, silver weld spots, etc. For packaging, various types are offered according to product post-processing requirements, such as reels for reeled terminals, cardboard packaging in several batches, loaders for special parts.

Mat-Kontak’s team has extensive experience in metal stamping and equipment maintenance. This helps us greatly in ensuring the correct manufacture and excellent service of our products. Mat-Kontak’s Engineering and Quality departments work together to continuously improve our industrial processes and quality.

We also have other auxiliary industrial equipment such as feeders, winders, lubricators, cutters, etc. used for product manufacture. During product manufacture, several types of surface finish can be defined during pre- or post-processing phases, such as tinning, plating, galvanisation, silver weld spots, etc. For packaging, various types are offered according to product post-processing requirements, such as reels for reeled terminals, cardboard packaging in several batches, loaders for special parts.

Mat-Kontak’s team has extensive experience in metal stamping and equipment maintenance. This helps us greatly in ensuring the correct manufacture and excellent service of our products. Mat-Kontak’s Engineering and Quality departments work together to continuously improve our industrial processes and quality.